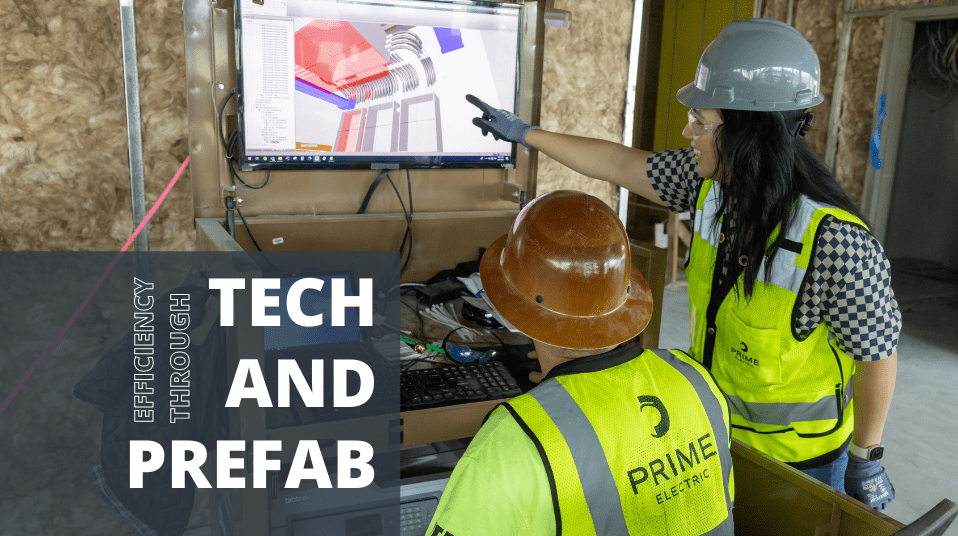

Before AutoCAD and Revit, Contract documents and hand drawings were the early foundations of construction plans. Technology has transformed the construction space, allowing for better installation and production data, visualization, precise measurements, and the efficiency to make necessary changes to any project. This is managed all before the costly setbacks and errors that can plague a project in the field. Prime Electric’s approach to prefabrication and Virtual Construction Services (VCS) revolves around our core value: continuous improvement. We’ve refined our processes to the next level, allowing our electricians to be more efficient and passing cost-savings to our customers.

A major advantage that PRIME benefits from is the many team members in our Prefab and VCS departments who have years of field experience. They’re able to bring their hands-on installation knowledge from the field and apply that knowledge to a virtual design. This approach ensures a design for installation that is both efficiently constructable and employs our standard Prefab assemblies. VCS collaborates with Prefab to ensure that the installation design provides an insight into early prefab assembly production schedules and releases. These schedules are set-up documentation to support the fields installation schedule on-site. This alignment enables the field team to tailor their installation approach to line up with their assembly packages. As technology continually develops, VCS and Prefab embraces the growth and continuously forecasts and adapts – which allows us to be scalable, increasing our volume as needed. Our standardization approach ensures our consistency of procedures across other regions.

Watch our latest video below to see the Prefab process.